Ciak Power multi material cutter

Ciak Power is the only multi material cutter able to cut up to 20 mm thick.

A 100% Made in Italy concept where each option, each idea is linked to the others to make a versatile result.

Ciak Power is the only multi material cutter able to cut up to 20 mm thick.

A 100% Made in Italy concept where each option, each idea is linked to the others to make a versatile result.

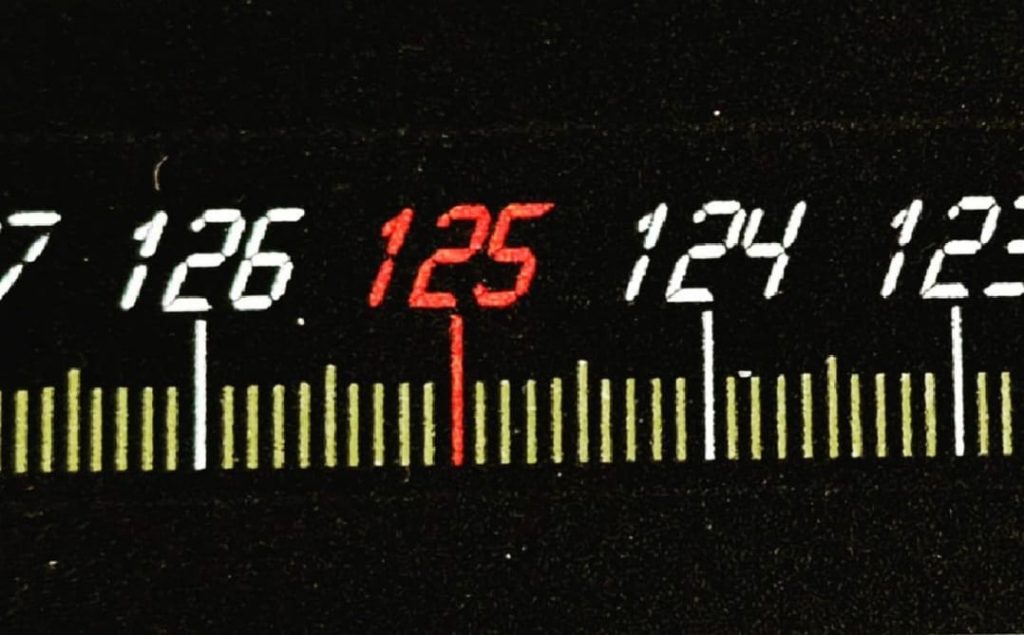

The frontal depth regulator displays 24 positions (they correspond to 20 mm.)

Set it on the “all down” position to get a through cut.

To cut in several passes we advise to set the regulator on “2” and score, then increase the depth.

The number of cuts depends by the material (hardness and thickness).

The great innovation you find in this machine is the side display that allows to set the blade in 4 different positions. It makes the machine to cut properly up to 20 mm. without any blade deflection in cutting thin panels. The blade adjustment system allows to cut a 5 mm. thick panel by setting the blade 5 mm. out or a 10 mm panel by setting the blade 10 mm out. The blade completely sinks into the material so the operator gets only power not blade deflection!

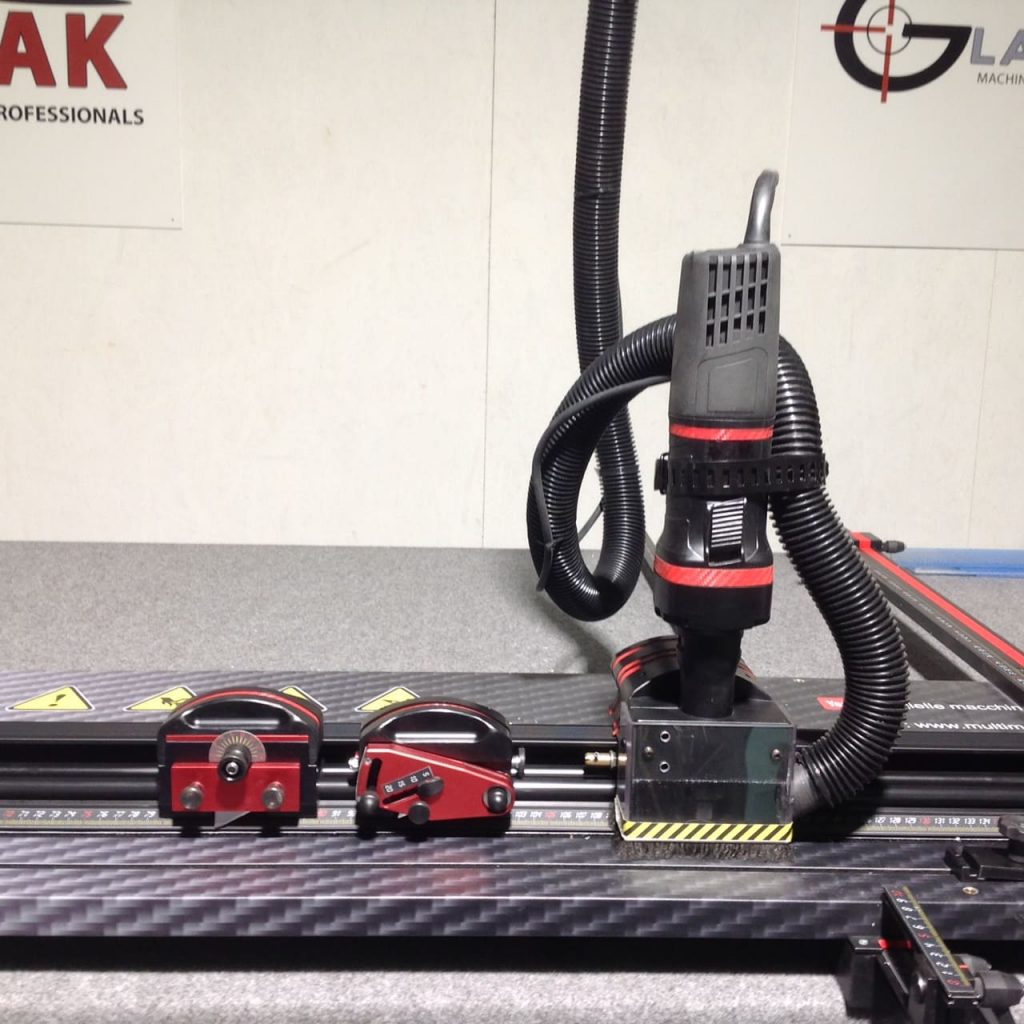

The core of the concept is the modularity. Build your super multi material cutter one part at a time and cut any substrate you need.

Are you using a Ciak Power? Upgrade it to Ciak Bomber! Buy the Bomber’s kit (discounted for manual Ciak owners) and go electric!

You can use on the same bar two trolleys: your manual Ciak’s one (needed to cut light materials that would be melt by the electric milling tool) and the electric Bomber’s one.

Do you want to use your Ciak Power to cut like a professional dibond, plexiglass, mirror, glass or to make your customized carton boxes? Order a Ciak Professional trolley and set it on the same bar: your super-multi material cutter is ready! Some Ciak Power’s options fit Ciak Professional too. See videos.

Two manual models, Ciak Professional e Ciak Power, seven different measures each, many options to square, cut glass and mirrors. Dibond/plexiglass kit allows to cut like a professional. Magic box makes you able to produce carton boxes. Ciak can be used as a unit or it can be fixed to the table. It is also available a working surface too (see photo) that is the same we use for electric Ciak Bomber.

We are proud of the fact Ciak is an open project. We are always listening the market to make an idea into a product. That’s really a key point in our product philosophy.

Ciak multi material cutters are cutting edge products. We supply technology in exclusive shapes and colors: innovative products in racing look!

The Ciak modular concept allows you to set contemporary or alternatively on the same bar three different trolleys! Cut a wide quantity of different materials by using each time the right tool: cut like a professional! Ciak Power and Ciak Bomber can be equipped with special kits to take your cuts to the next level.

We take care of the customers of ours: we projected left handed blade holders to allow left handed operators to work comfortably. We don’t produce serial machines only: we can customize them in many ways.

We can ship the machine set on customer’s needs: on request we can increase or decrease trolleys’ smoothness or the side lifters’ friction effect. Each customers is unique and he deserves his own machine. If the cutter is used by many different operators we supply it with standard settings. Each operator can adjust the settings by himself.